Product features

■ Level and interface measurement in liquids and bulk solids.

■ The user interface of the product can be adjusted through mobile phone.

■ Remote parameter setting can be supported without going to on-site.

■ Density fluctuations, steam generation or strong pressure and temperature fluctuations do not influence the measuring result.

■ Build-up on the probe or the vessel wall do not influence the measurement.

■ Product adopts innovative multi-echo tracking technology, built-in storage of factory pre-calibration data, reliable measurement under fluctuating liquid levels and foams.

■ The product has high cost performance, supports OEM/ODM, and has a complete set of electronic modules.

■ Product is cost-effective, supports OEM/ODM, electronic modules are available.

■ With inside overvoltage protection.

■ It supports the connection of tank tables to achieve distributed display and debugging.

Specifications

| Document Download | |

|

|

|

|

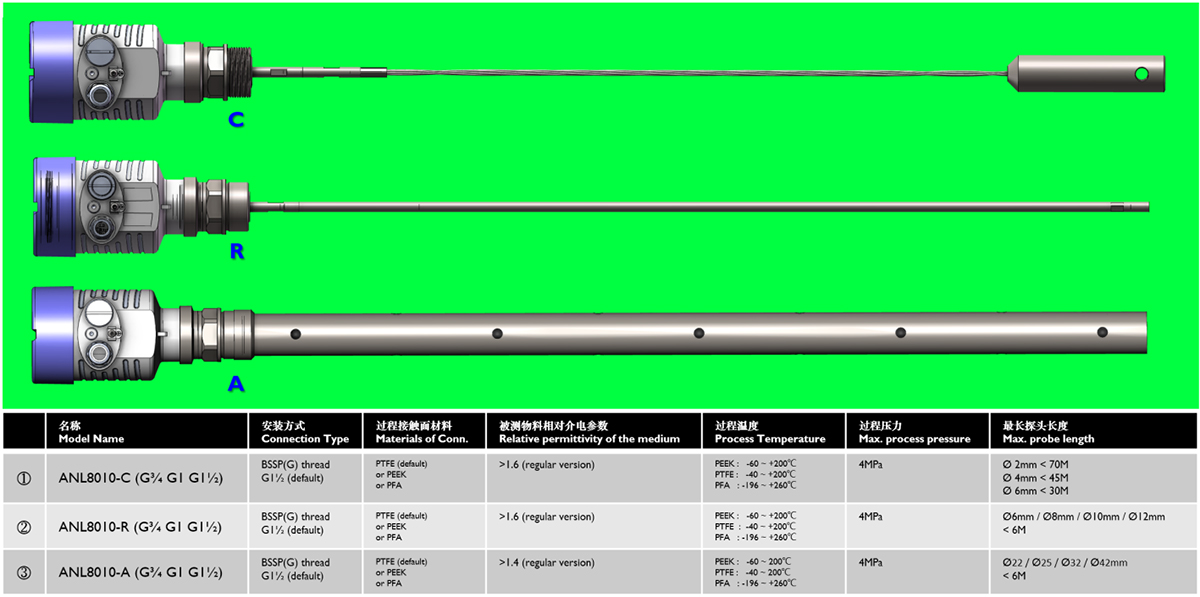

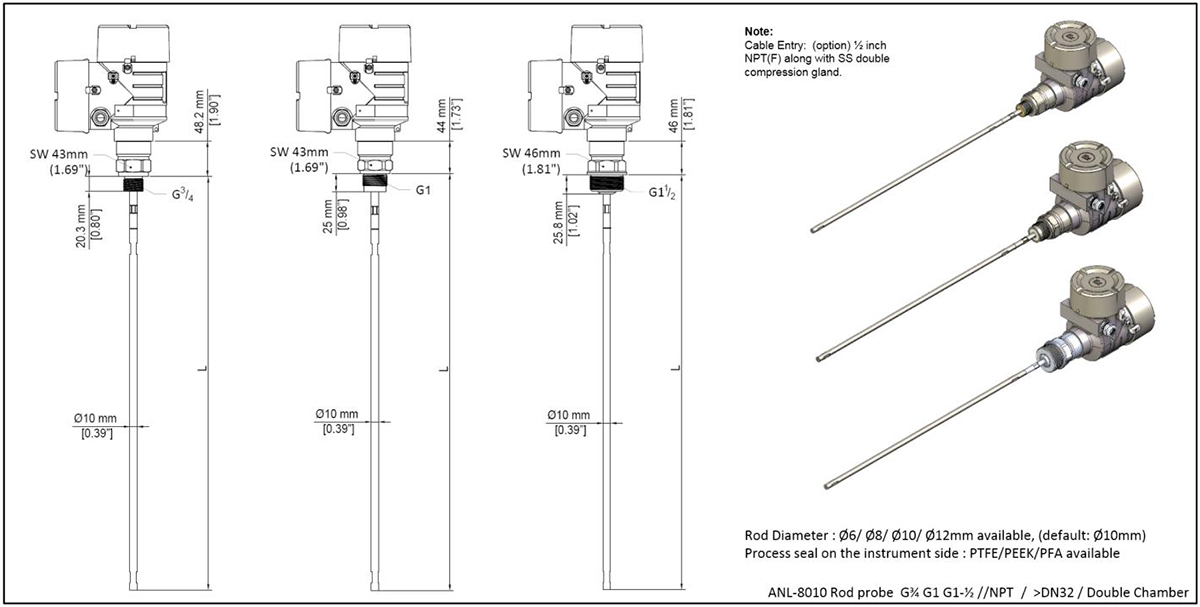

| ANL-8010 - X | Rod | Cable | Coax |

| Max. measuring range | Max. 10m / Level or Level & Interface | Max. 45m / Level or Level & Interface | DK >1.4 Max. 6m / Level or Level & Interface |

| DK value | DK >1.4 | DK >1.6 @ ≤30m, DK >2.0 @ >30m | DK >1.2 |

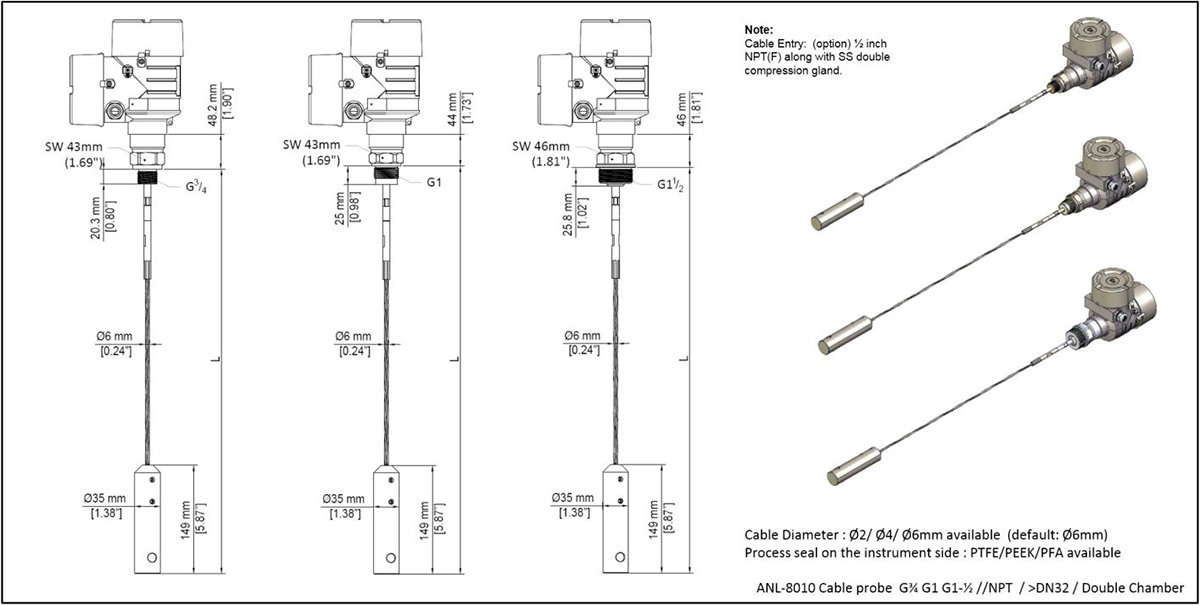

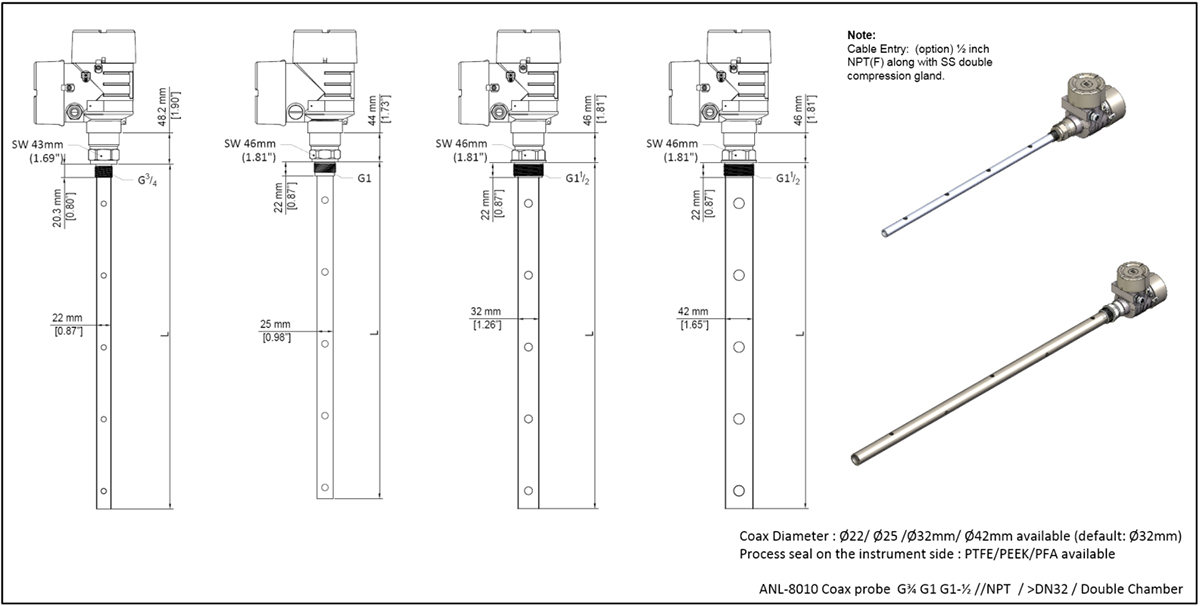

| Probe | Ø 8 / Ø 10 (default) / Ø 12mm | Ø 2 / Ø 4 / Ø 6mm (default) | Ø 22 / Ø 32(default) / Ø 42mm |

| Process fitting / Material wetted parts |

Thread G¾, G1, G1½, NPT/ Flanges >= DN25 304L/316L/Alloy C, PEEK / PTFE (default) / PFA |

Thread G¾, G1, G1½, NPT / Flanges >= DN50 304L/316L/Alloy C, PEEK / PTFE (default) / PFA |

Thread G¾, G1, G1½, NPT /Flanges >= DN50 304L/316L/Alloy C, PEEK / PTFE (default) / PFA |

| Ambient temperature | -40 … +85 °C / -60 … +105 °C (cool version) | ||

| Process temperature | -60°C … +200°C / PEEK , -40°C … +200°C / PTFE, -195°C … +260°C / PFA | ||

| Max. process pressure | -1 … 4MPa | -1 … 4MPa | -1 … 4MPa |

| Measuring accuracy |

liquid level: ±2 mm medium level ,Interface: ±5 mm |

liquid level: ±2 mm@<=15M, ±6 mm@>15M medium level, Interface: ±8 mm |

liquid level: ±1 mm medium level, Interface: ±5 mm |

| Signal output | 4-20 mA/HART7 2-wire, 4-20 mA/HART7 4-wire, Profibus PA / DP, Ethernet-APL, Modbus protocol 4-wire | ||

| Variables influencing meas. accuracy |

Specifications for the digital measured value: Temperature drift - Digital output: ±1mm/10K relating to the max. measuring range or max. 15 mm Additional deviation through electromagnetic interference acc. to EN-61326: < ±10 mm Specifications apply also to the current output Temperature drift - Current output: ±0.01%/10K relating to the 16.7 mA span or max. ±0.15% Deviation in the current output due to digital/analogue conversion Non-Ex and Ex-ia version: < ±1μA; Ex-d-ia version: < ±1μA Additional deviation through electromagnetic interference acc. to EN-61326: < ±150μA |

||

| Indication/Adjustment |

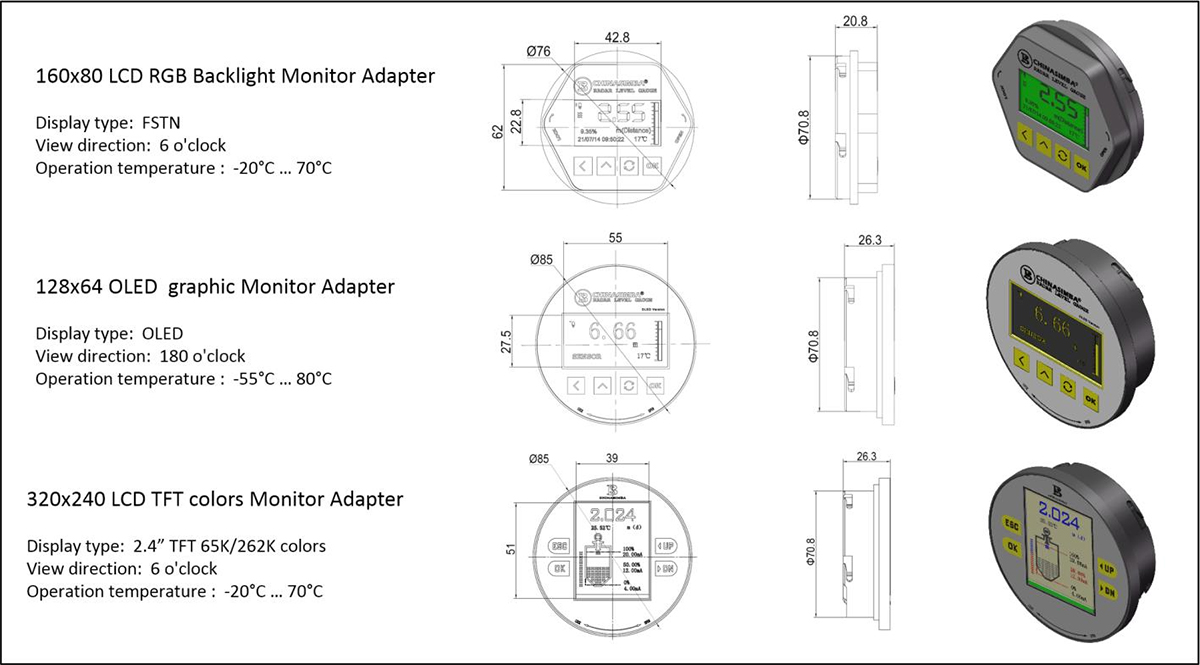

1. 160x80 LCD FSTN RGB backlight monitor adapter with keyboard module, operation Temp. -20°C … 70°C. or 128x64 OLED monitor adapter with keyboard module, operation Temp. -55°C … 80°C. (option) or 230x240 LCD TFT colors monitor adapter with keyboard module, operation Temp. -20°C … 70°C. (option only for 4-wrie system) 2. (APP) Radar MobileManager via BT wireless connection 3. (PC software) Radar PCManager /or Via a PC with PACTware/DTM (an interface converter AiW-305 USB CONNECT is required) |

||

| Power supply | 14.5V ~ 40 VDC / Load resistor > 600Ω | ||

| Wireless communication | Bluetooth 5.0 (Bluetooth 4.0 LE compatible), communication range 40m, in rainy day 20m | ||

| Approvals | Ex ia IIC T6 Ga IP67; Ex d IIC T6 Gb IP67 | ||

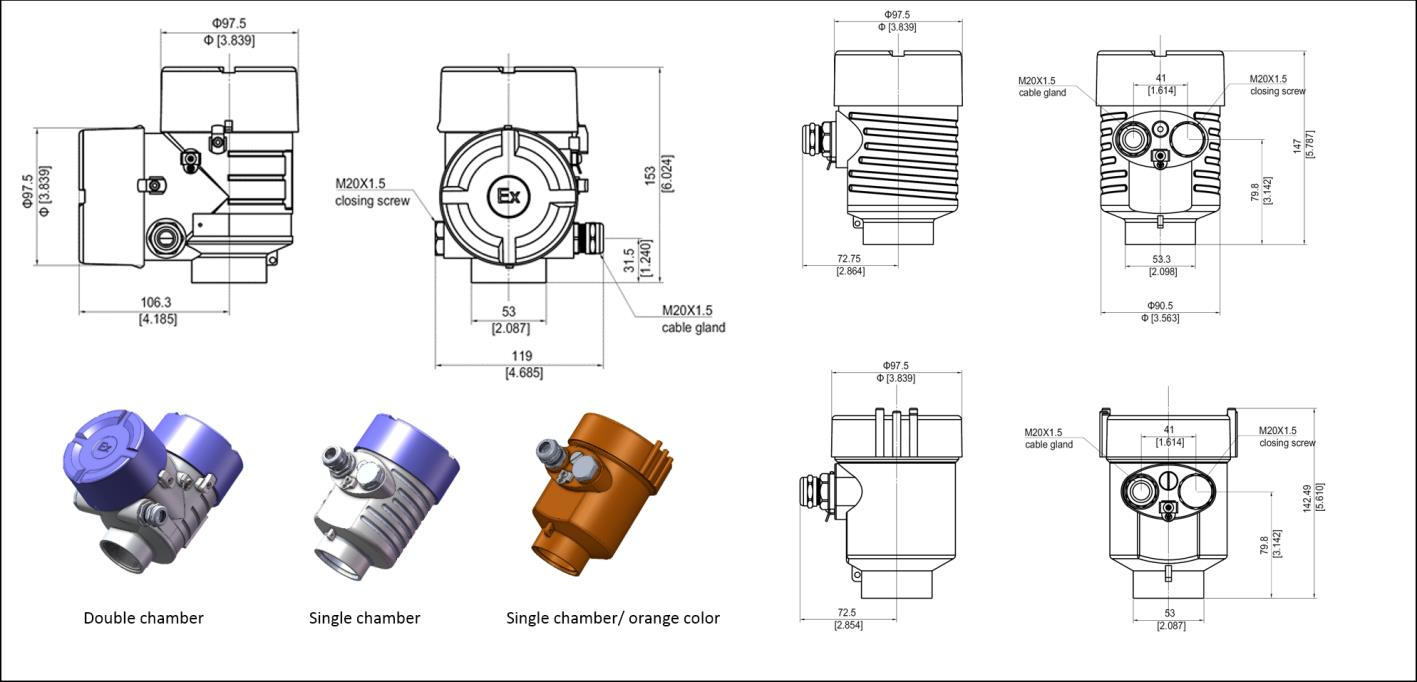

| Housing | Single chamber / Double chamber, Aluminum / Stainless steel / Plastic PBT, IP66 / IP67 / IP68 | ||

| Applications | Storage silos, storage tanks, liquids with smooth surface | Storage tanks, liquids with agitated surface, high storage silos, silos with product movement | Storage tanks, liquids with low dielectric constant, vessel with installations |

|

|

|

|

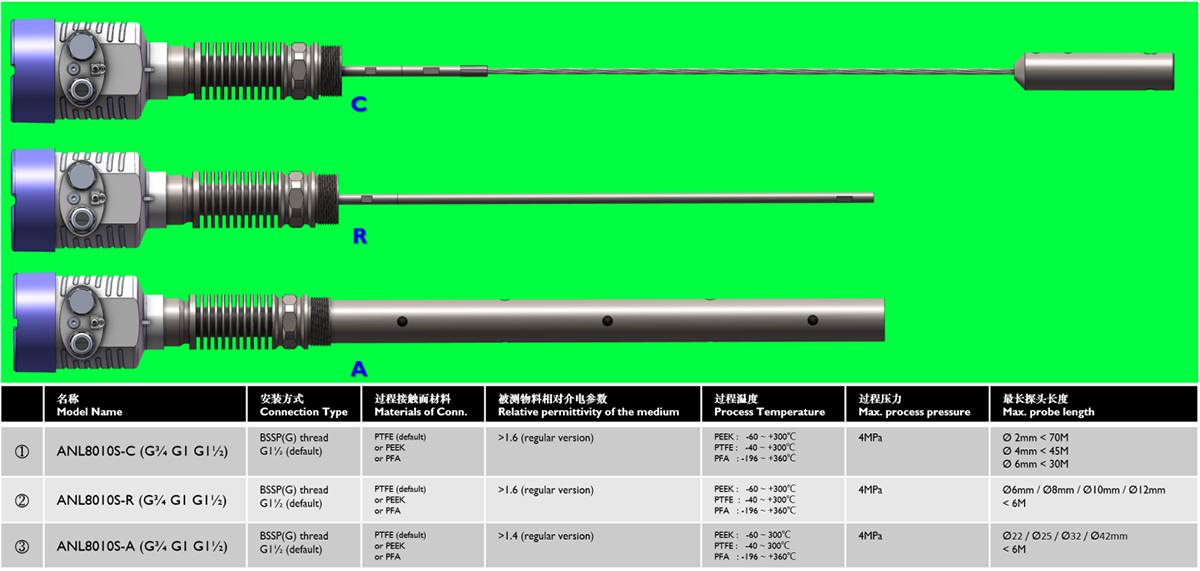

| ANL-8010S- X | Rod | Cable | Coax |

| Max. measuring range | Max. 10m / Level or Level & Interface | Max. 45m / Level or Level & Interface | DK >1.4 Max. 6m / Level or Level & Interface |

| DK value | DK >1.4 | DK >1.6 @ ≤30m, DK >2.0 @ >30m | DK >1.2 |

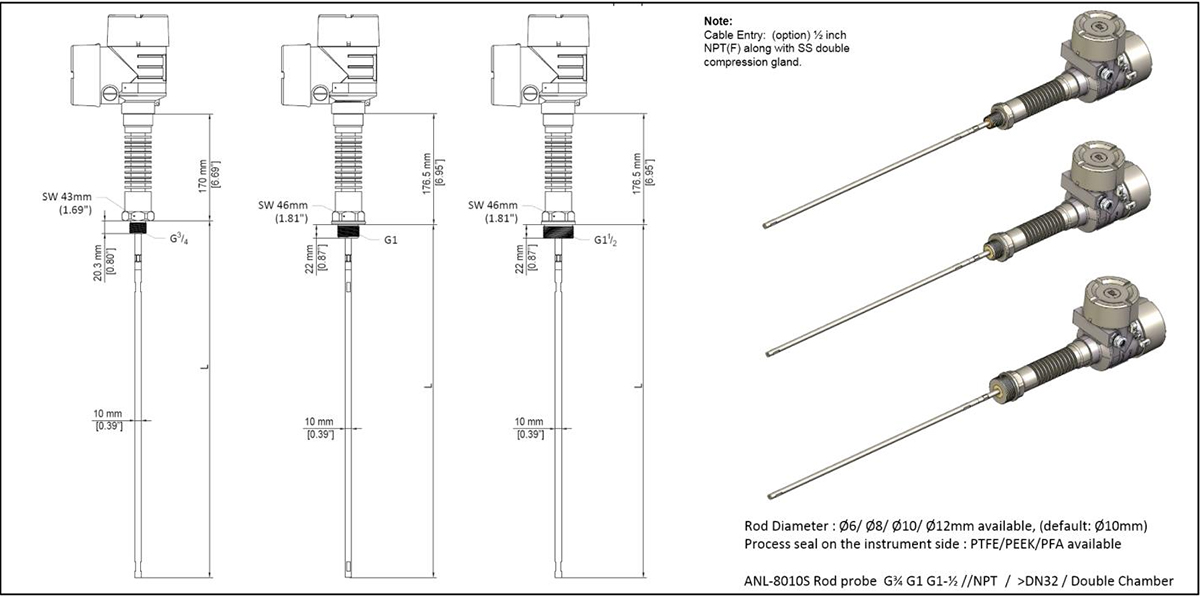

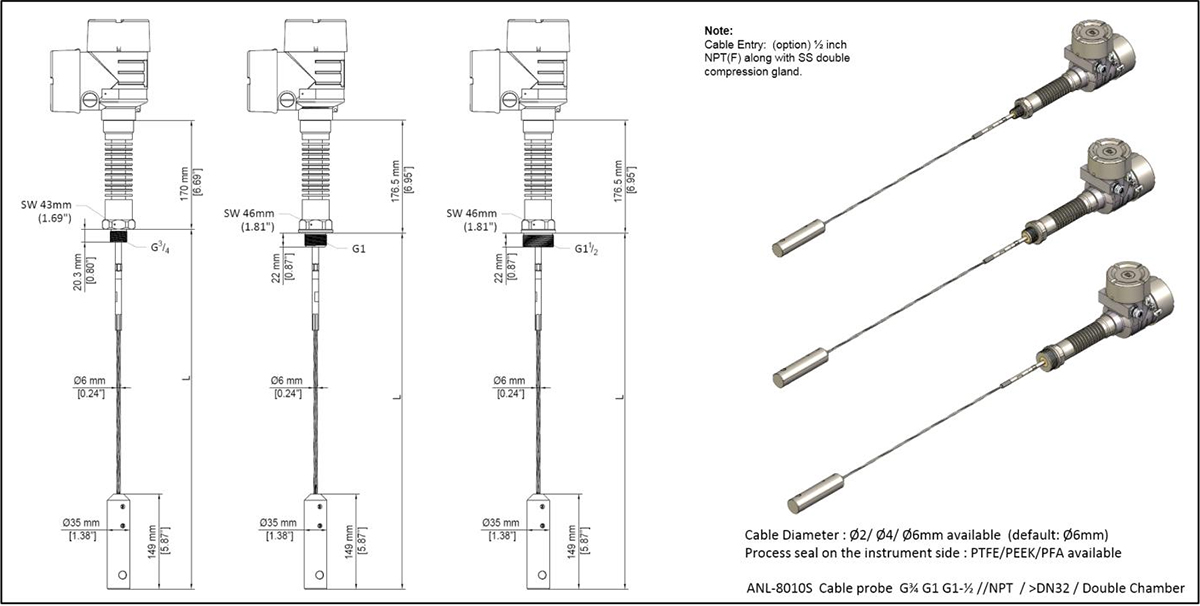

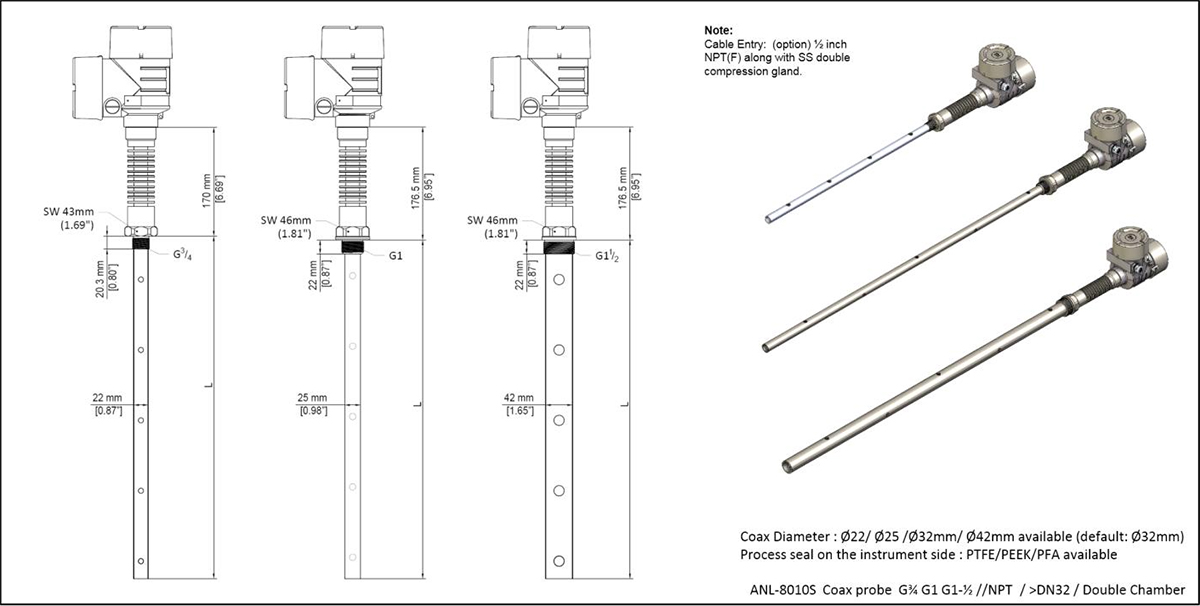

| Probe | Ø 8 / Ø 10 (default) / Ø 12mm | Ø 2 / Ø 4 / Ø 6mm (default) | Ø 22 / Ø 32(default) / Ø 42mm |

| Process fitting / Material wetted parts |

Thread G¾, G1, G1½, NPT/ Flanges >= DN25 304L/316L/Alloy C, PEEK / PTFE (default) / PFA |

Thread G¾, G1, G1½, NPT / Flanges >= DN50 304L/316L/Alloy C, PEEK / PTFE (default) / PFA |

Thread G¾, G1, G1½, NPT /Flanges >= DN50 304L/316L/Alloy C, PEEK / PTFE (default) / PFA |

| Ambient temperature | --40 … +85 °C / -60 … +105 °C (cool version) | ||

| Process temperature | -60°C … +300°C / PEEK , -40°C … +300°C / PTFE , -195°C … +360°C / PFA | ||

| Max. process pressure | -1 … 4MPa | -1 … 4MPa | -1 … 4MPa |

| Measuring accuracy |

liquid level: ±2 mm medium level ,Interface: ±5 mm |

liquid level: ±2 mm@<=15M, ±6 mm@>15M medium level, Interface: ±8 mm |

liquid level: ±1 mm medium level, Interface: ±5 mm |

| Signal output | 4-20 mA/HART7 2-wire, 4-20 mA/HART7 4-wire, Profibus PA / DP, Ethernet-APL, Modbus protocol 4-wire | ||

| Variables influencing meas. accuracy |

Specifications for the digital measured value: Temperature drift - Digital output: ±1mm/10K relating to the max. measuring range or max. 15 mm Additional deviation through electromagnetic interference acc. to EN-61326: < ±10 mm Specifications apply also to the current output Temperature drift - Current output: ±0.01%/10K relating to the 16.7 mA span or max. ±0.15% Deviation in the current output due to digital/analogue conversion Non-Ex and Ex-ia version: < ±1μA; Ex-d-ia version: < ±1μA Additional deviation through electromagnetic interference acc. to EN-61326: < ±150μA |

||

| Indication/Adjustment |

1. 160x80 LCD FSTN RGB backlight monitor adapter with keyboard module, operation Temp. -20°C … 70°C. or 128x64 OLED monitor adapter with keyboard module, operation Temp. -55°C … 80°C. (option) or 230x240 LCD TFT colors monitor adapter with keyboard module, operation Temp. -20°C … 70°C. (option only for 4-wrie system) 2. (APP) Radar MobileManager via BT wireless connection 3. (PC software) Radar PCManager /or Via a PC with PACTware/DTM (an interface converter AiW-305 USB CONNECT is required) |

||

| Power supply | 14.5V ~ 40 VDC / Load resistor > 600Ω | ||

| Wireless communication | Bluetooth 5.0 (Bluetooth 4.0 LE compatible), communication range 40m, in rainy day 20m | ||

| Approvals | Ex ia IIC T6 Ga IP67; Ex d IIC T6 Gb IP67 | ||

| Housing | Single chamber / Double chamber, Aluminum / Stainless steel / Plastic PBT, IP66 / IP67 / IP68 | ||

| Applications | Storage silos, storage tanks, liquids with smooth surface | Storage tanks, liquids with agitated surface, high storage silos, silos with product movement | Storage tanks, liquids with low dielectric constant, vessel with installations |

ANL-8010 2GHz GWR radar level Gauges Overview

| 结构规格 Series |

8010 Regular version |

8010S HTversion |

8010H HTHP version |

8010P Remote connection |

8010PH Remote connection |

|---|---|---|---|---|---|

| Exia/Exd Single/Double Chamber |

Single/Double | Single/Double | Single/Double | Single/Double | Single/Double |

| Cable probe/SS304/SS316 | 2/4/6mm(default) | 2/4/6mm(default) | 4mm/6mm(default) | 4mm/6mm(default) | 6mm(default) |

| Rod probe/SS304/SS316 | 6/8/10(default)/12mm | 6/8/10(default)/12mm | 8mm/10mm/16mm | 8mm/10mm/16mm | 8mm/10mm/16mm |

| Coax probe/SS304/SS316 | 22/25/32/42mm | 22/25/32/42mm | 22/25/32/42mm | 22/25/32/42mm | 22/25/32/42mm |

| Max.process pressure | 4MPa | 4MPa | <=4MPa | <=4MPa | <=4MPa |

| Level/interface | Level or Level/Interface | Level or Level/Interface | Level or Level/Interface | Level or Level/Interface | Level or Level/Interface |

| Process fittings:Pipe thread | G¾,G1,G1½//NPT | G¾,G1,G1½//NPT | G¾,G1,G1½,G3//NPT | G¾,G1,G1½//NPT | G¾,G1,G1½//NPT |

| Self-struc.process Temp.[1] | -60℃~+200℃/PEEK -40℃~+200℃/PTFE -196℃~+260℃/PFA |

-60℃~+300℃/PEEK -40℃~+300℃/PTFE -196℃~+360℃/PFA |

-196℃~+450℃ | -60℃~+200℃/PEEK -40℃~+200℃/PTFE -196℃~+360℃/PFA |

-196℃~+850℃ |

| Config Min.flange size | DN32 | DN32 | DN32 | DN32 | DN32 |

| Process seal on the instrument side(cable/rod lead through) |

PTFE/PEEK/PFA | PTFE/PEEK/PFA | Ceramics | PTFE/PEEK/PFA | Zirconia Ceramic |

O-ring list

| Code | Global Name | CN Name | CN Brand | Shore A | Temperature |

|---|---|---|---|---|---|

| N | None | ||||

| K |

Kalrez6375 Perfluoroelastomer |

全氟醚橡胶 |

TRUFLOUREZ-T23 |

75 | -15℃~230℃ |

| TRUFLOUREZ-T80 | 70 | -15℃~310℃ | |||

| TRUFLOUREZ-T32 | 75 | -15℃~325℃ | |||

| TRUFLOUREZ-T26 | 70 | -15℃~260℃ | |||

| TRUFLOUREZ-T30 | 75 | -15℃~300℃ | |||

| TRUFLOUREZ-T95 | 60 | -15℃~300℃ | |||

| E |

EPDM |

三元乙丙橡胶 |

TRUFLOUREZ-EPDM | SA40-90 | -5℃~300℃ |

| V |

Viton Fluoroelasromer |

氟橡胶 |

Ref.to Viton O-ring list | ||

| B |

NBR |

丁腈橡胶 |

TRUFLOUREZ-NBR | SA50-90 | -40℃~120℃ |

| L |

Low-Temperature Viton Fluoroelasromer |

低温氟橡胶 |

Ref.to Viton O-ring list | ||

| F |

FVMQ |

氟硅橡胶 |

TRUFLOUREZ-FVMQ | SA45-80 | -60℃~230℃ |

| P | PTFE seal | 四氟弹簧密封圈 | FMH-PTFE o-ring | SB-200 | -200℃~300℃ |

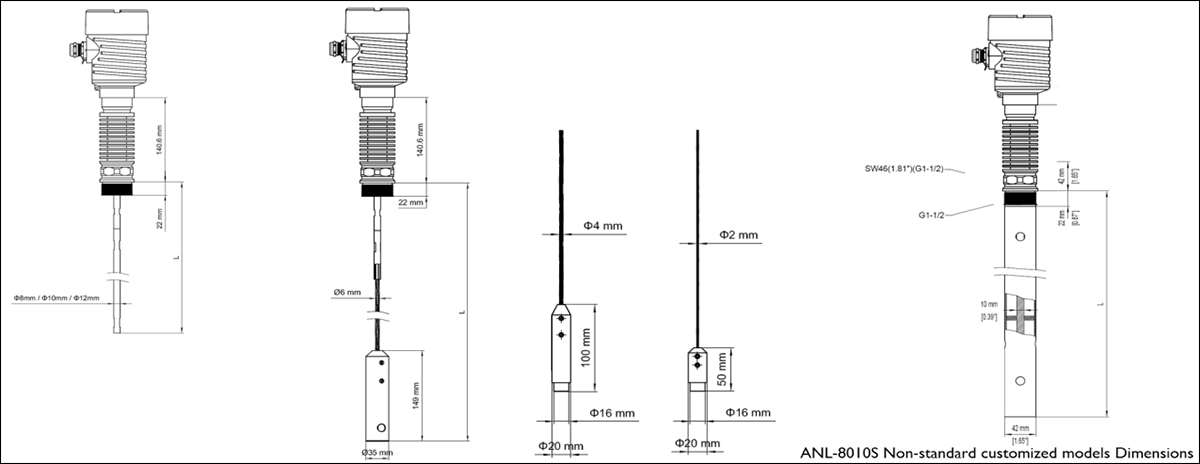

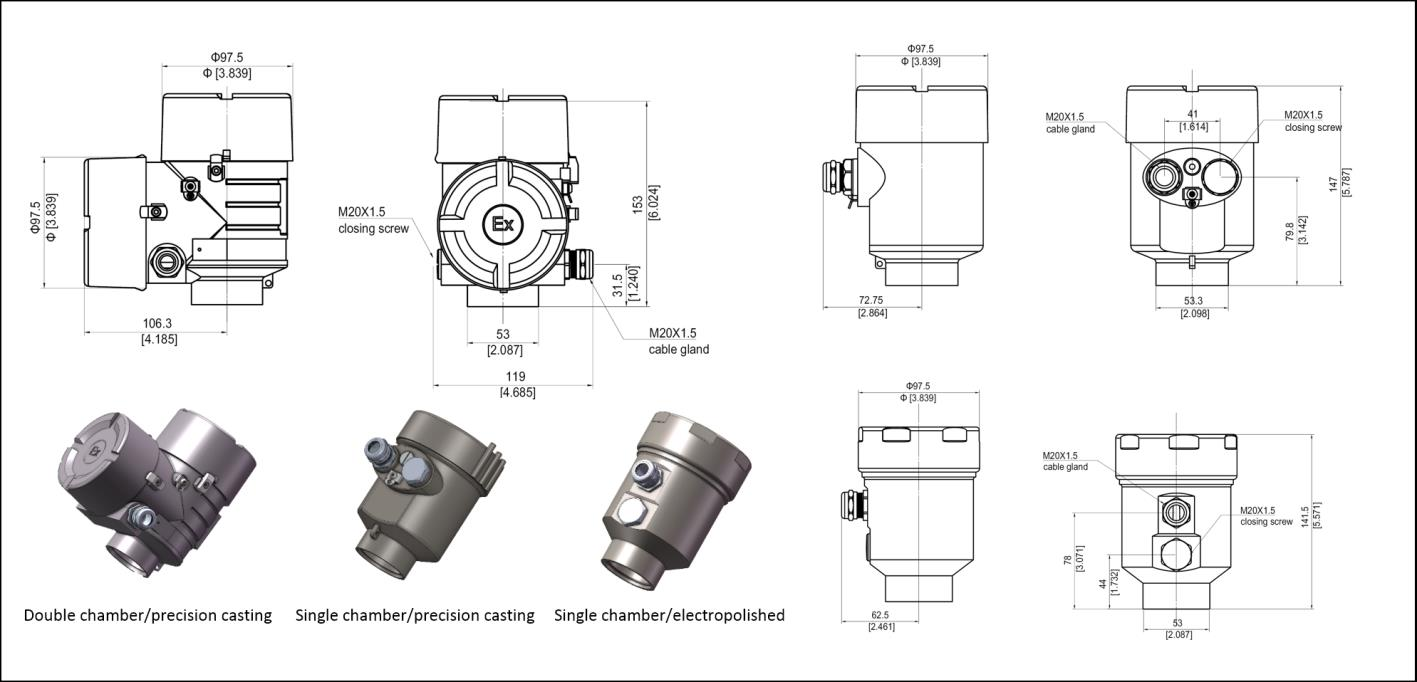

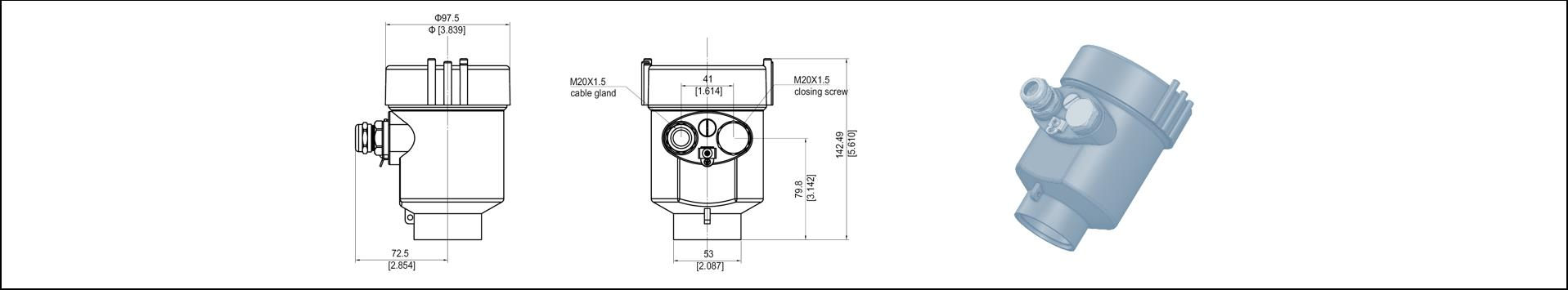

Product dimensions

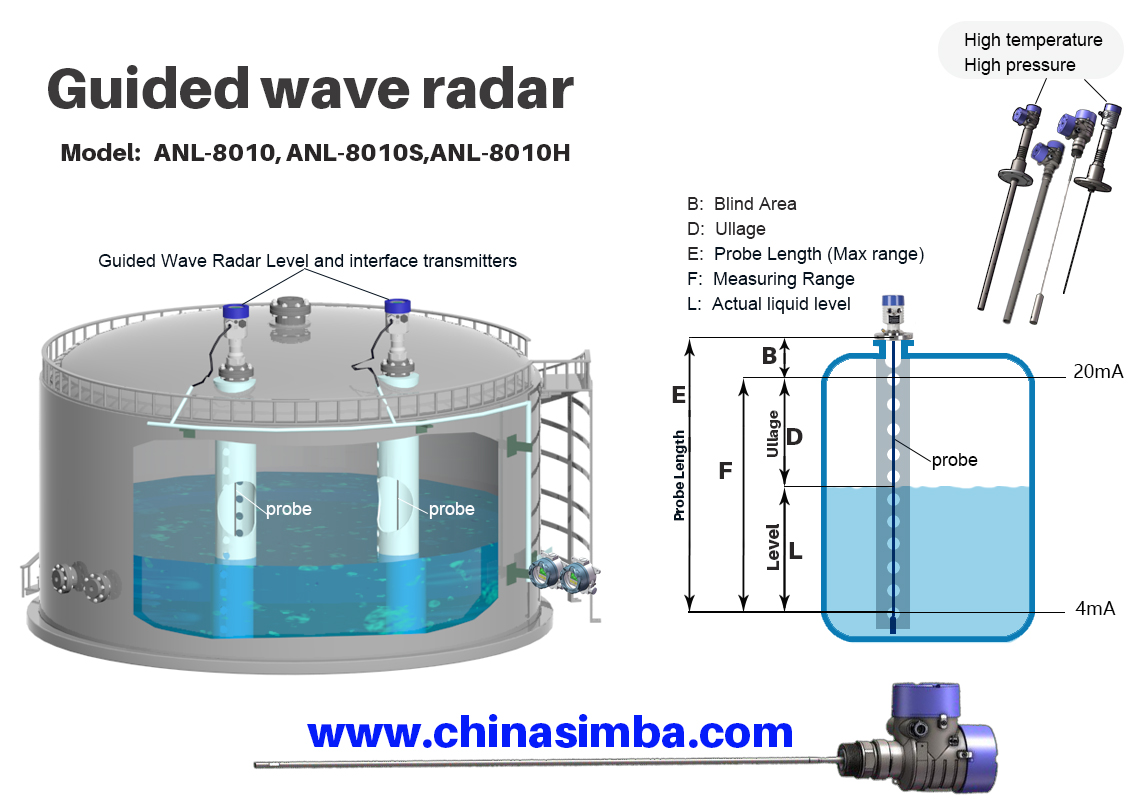

Application installation

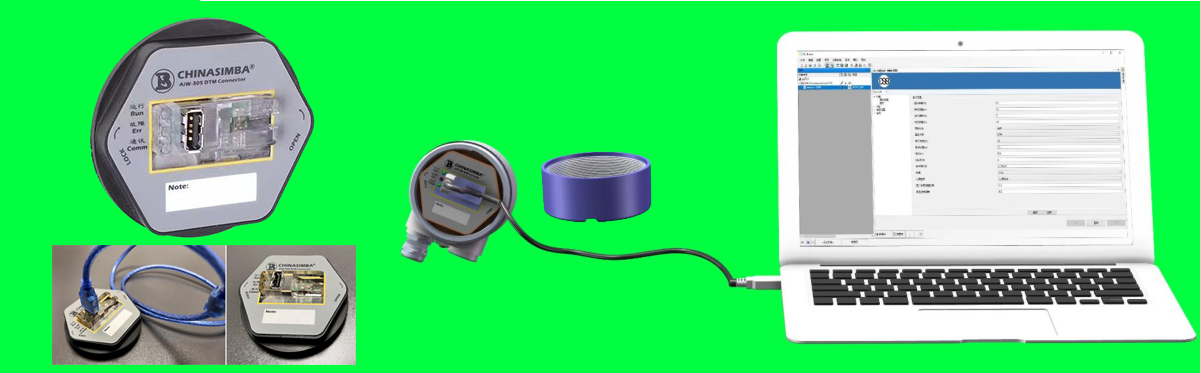

Product debugging method

ANL-8010 can be directly connected and debugged with a computer equipped with PACTware/DTM software through the AiW-305-USB converter.

DTM Adapter for ANL-8010

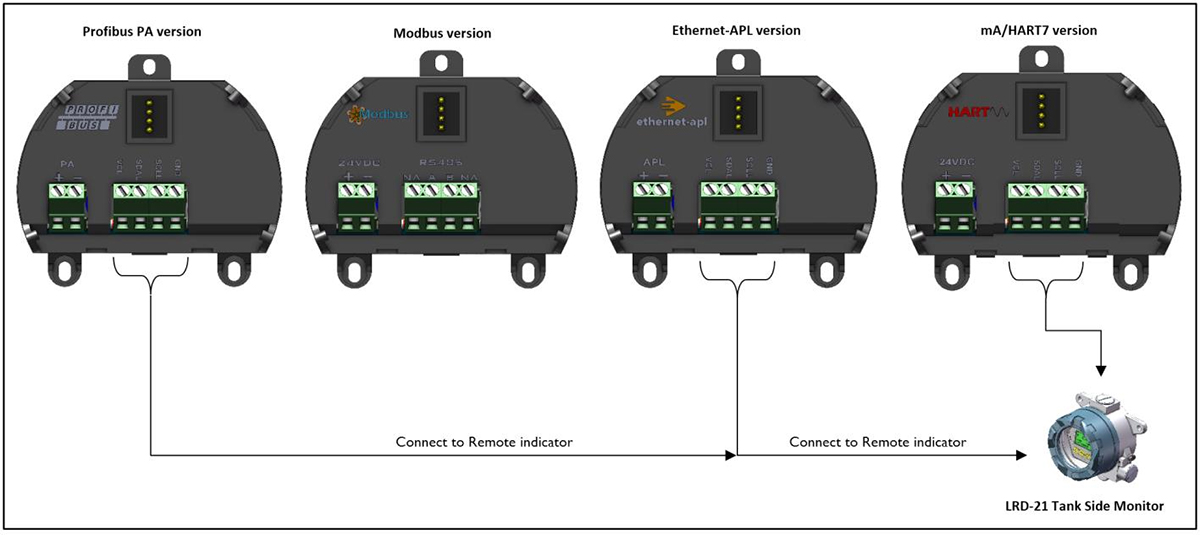

Remote programmer cum Indicator Adapters

Remote indicator via Bluetooth communication

ANL-9080 radar level transmitters (with Bluetooth function) can be connected to mobile phone through Bluetooth wireless system. The mobile phone needs to install the RadarMobileManager APP. This is a free registered APP (Android and IOS etc.) software, which can be downloaded and installed directly in major APP Stores, or please contact the relevant product suppliers.

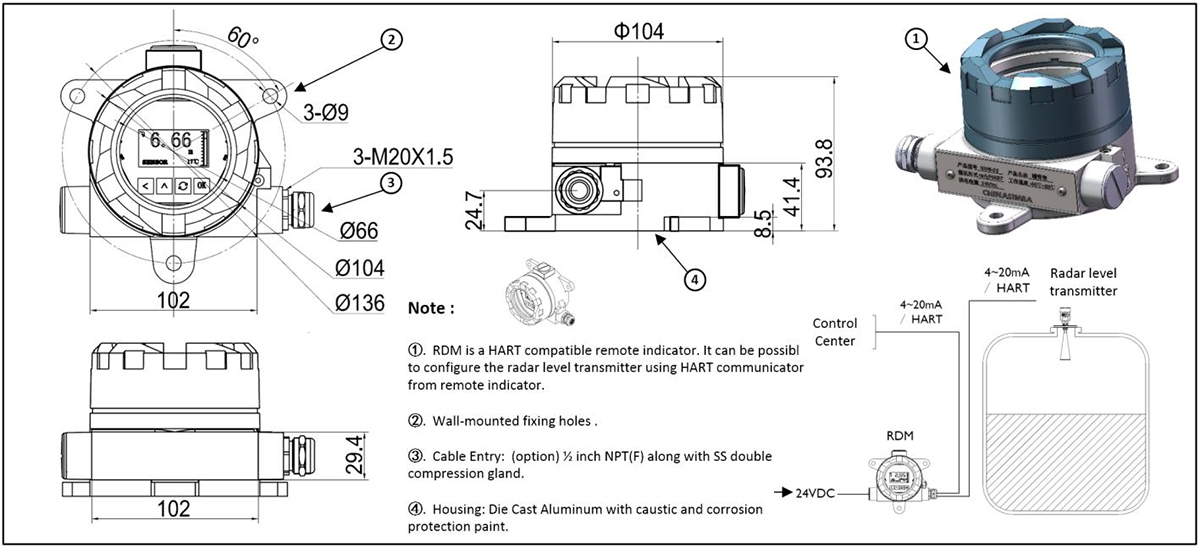

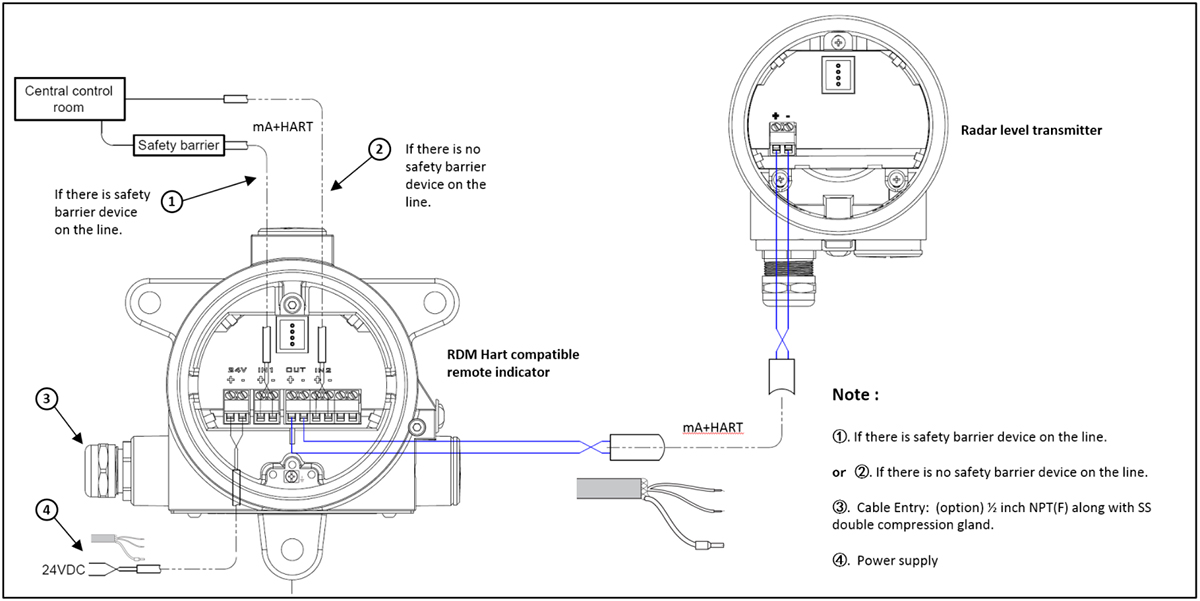

Remote indicator with HART compatible (RDM-25)

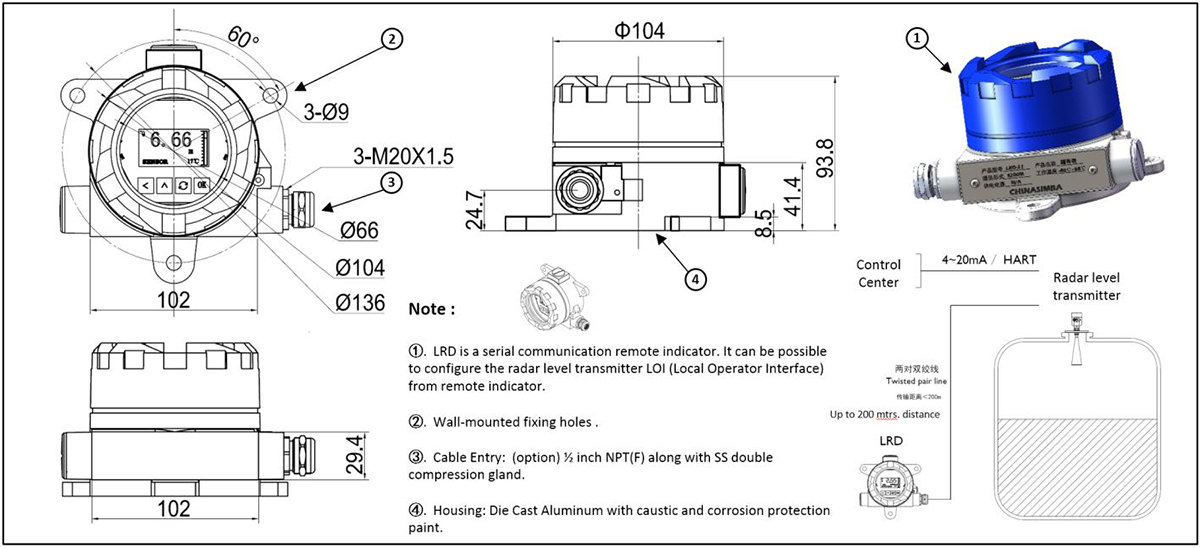

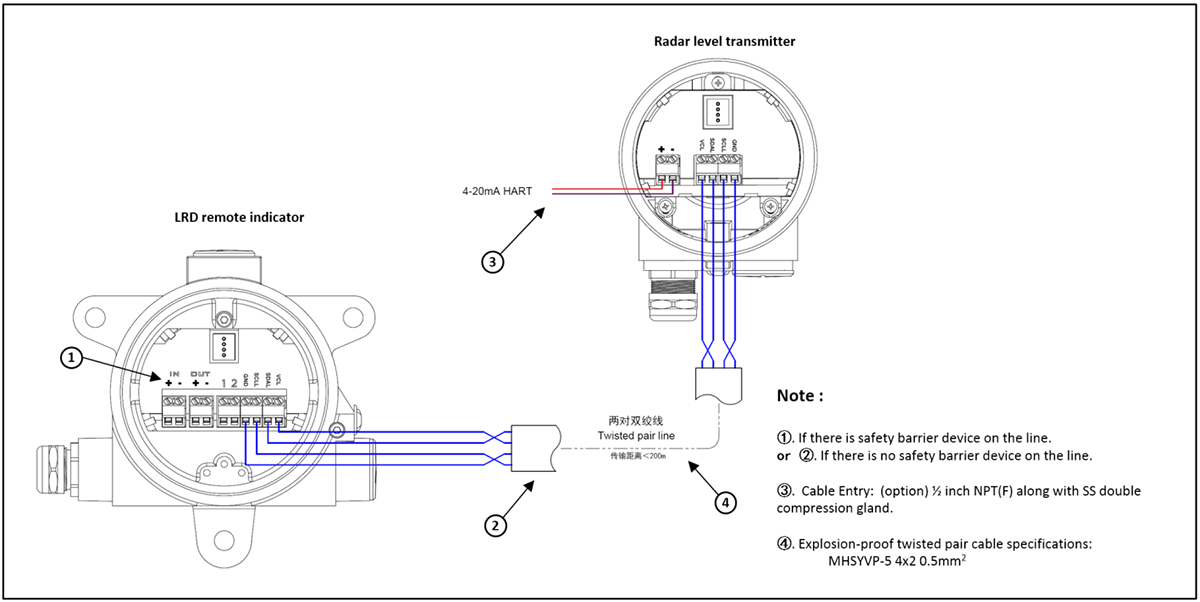

Remote indicator via Serial communication (LRD-21)

Indication/Adjustment LOI Adapter