Features

■ Non-contact high-precision 3D scanning volume measurement radar, which can detect the material level, volume, mass, temperature and other information in real time

■ 0.12THz mmWave terahertz FMCW synthetic aperture radar (SAR) technology

■ Ultra-Wideband, realizing long-distance level measurement, radar imaging, and accurate volume calculation of bulk materials with irregular surfaces

■ Strong anti-interference ability, high precision, high-resolution imaging

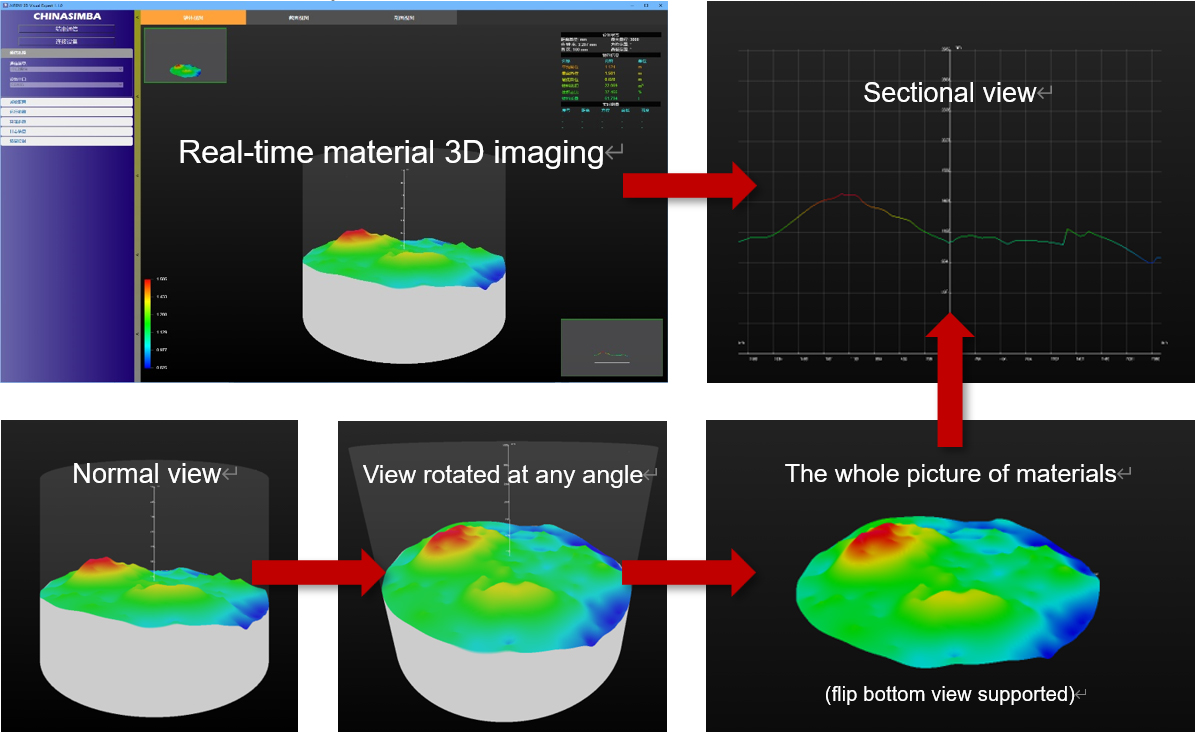

■ Using standard heat map imaging display method to accurately display the status of the stereoscopic image in the warehouse

■ Various scanning modes can be selected for imaging, it only takes 60 seconds to complete 360° real-time automatic continuous scanning and imaging/180° pitch angle at high speed

■ Supports wired/wireless data transmission, 2-way standard 4-20mA (HART) current output, 2-way MODBUS output, 1-way relay alarm signal and other output methods

■ High-precision 3D scanning imaging technology realizes "what you see is what you get"

Applications

It is suitable for tanks, silos, warehouses, open containers and outdoor accumulation of powder or bulk solids, etc., where it is necessary to monitor the volume and state of bulk materials, and can be widely used in pellets, granules, powders and other lumps solids, such as: grain, seed and feed and other raw materials processing industry, food and beverage industry, energy, power raw material processing, cement industry, plastics processing industry, mining and smelting industry, metal processing industry, chemical industry, glass manufacturing and processing industry, pulp and paper, raw wood processing industries.

Specification

| Document Download |

| 3D scanning scope | Polar mode: vector length (distance) 0.35~100.00m, pitch angle 0~90°, azimuth angle 0~360° (Center point: the origin of the center line of the flange plane) |

| 3D scanning performance | Sweep range: 0.11~0.14THz, radar slant range resolution: 30mm, radar azimuth resolution: 15mm |

| Volume measurement accuracy | High speed mode: scan imaging accuracy ±10mm, maximum volume error 12% Medium speed mode: scan imaging accuracy ±8mm, maximum volume error 6% Low speed mode: scan imaging accuracy ±3mm, maximum volume error 2% |

| Level measurement accuracy | Quadrature measurement accuracy ±1mm, slope distance measurement accuracy ±3mm |

| Sweep measurement response | Power-on output valid measurement data update time <30s, measurement data update time <15s (determined by scanning step and scanning range) {Level/Volume/Imaging} data update interval: High speed mode: 12mins/each full space scan (0<θ<90°, 0<φ<360°, continuous step) Medium speed mode: 5mins/each full space scan (0<θ<90°, 0<φ<360°, continuous step) Low speed mode: 2mins/each full space scan (0<θ<90°, 0<φ<360°, continuous step) |

| Radar imaging features | Standard thermal image bitmap pixels: 10,000 / 256 grayscale, calculating the minimum grid interval of 3D surface structure 3mm @10 meters sloping distance |

| Step features | Closed loop step motor scanning system: Azimuth scan range: 0~360°/ configurable (minimum step angle=1°) Pitch scan range 0~90°/ configurable (minimum step angle=0.1°) Stepping system encoder resolution:16000 P/R @ response frequency 30KHz |

| Antenna | Round FRP antenna protection cover, antenna beam angle 3° |

| Signal output/communication | 2-way RS-485 (MODBUS) 1-way 4-20mA / HART7 1-way 4-20mA (DAC instantaneous current output mode) 1-way Relay/high and low alarm output (250VAC/5A) 1-way 100M network interface Accessory options: system diagnostic interface / USB / SD card / optical fiber communication interface |

| Power Supply | 220VAC/150W or 24VDC/5A(option), IP67 aviation plug, mm2/AWG ≤0.785/18 |

| Ambient temperature/humidity | -40~85°C / ≤75%RH |

| Process temperature/pressure | -55~150°C / 860 ~ 1060 mbar (12,47 ~ 15,37psi) |

| Housing material | Anodized aluminum + FRP antenna protection cover |

| Protection | IP67 |

| Installation | Flange - DN200 |

| Standard lead-time | 15 weeks |

Imaging captures (multiple views can be switched arbitrarily, monitoring, observation and analysis for multiple purposes)

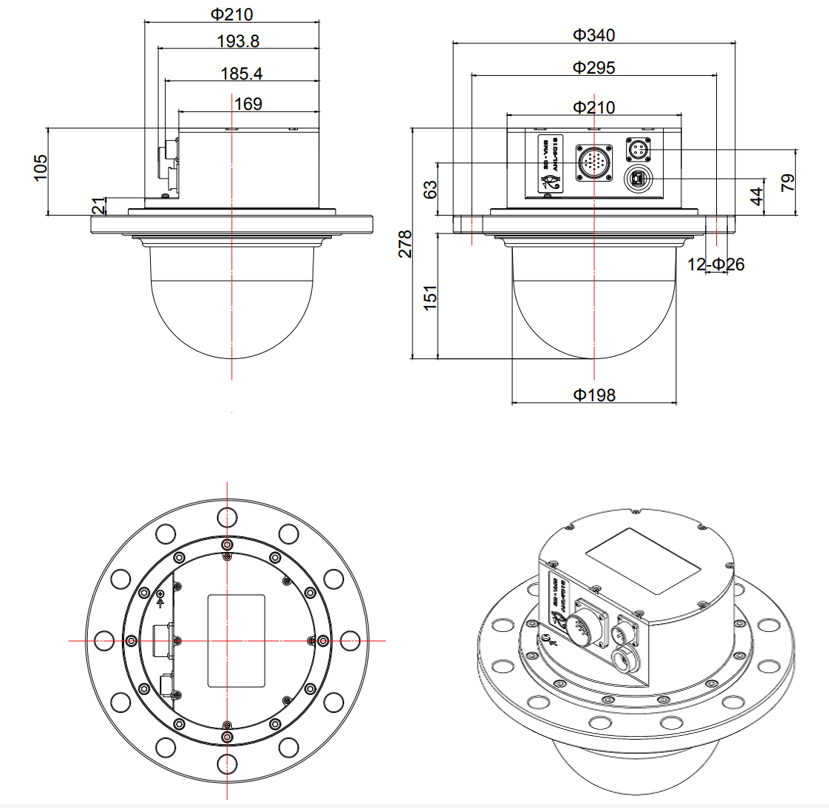

Dimensions