Characteristics

■ 80GHz Frequency FMCW radar system.

■ Measurement application in liquids, solids.

■ Chemical industry reaction tanks, reactors. Stirring and corrosive environment applications, also in steam.

Specifications

| ANL-9080N50 | Lens material PTFE | Lens material PEEK | N60 (cool version) |

|---|---|---|---|

| Max. measuring range | 40M for liquid, 30M for solids/powder | 40M for liquid, 30M for solids/powder | 40M for liquid, 30M for solids/powder |

| Tx/Rx frequency |

Tx/Rx frequency 76.2 to 80.2GHz Dynamic FM Sweep Bandwidth 1~4GHz (The adjustment FM range can be customized according to the ISM requirements of the customer’s region) |

||

| Near blind spot | < 100mm from the flange down surface | ||

| Meas. Principle | FMCW Radar System | ||

| Lens Antenna Medium | PTFE Φ50mm | PEEK Φ50mm | PEEK Φ50mm |

| Antenna beam / Gain | Beam angle 5°/ Gain 28.9dB | Beam angle 5°/ Gain 29.3dB | |

| Meas. Resolution | < 0.1mm (<10m range) | ||

| Meas. Accuracy | ±2 mm / ±1 mm (Precision Requirements Edition) | ||

| Ambient temperature | -40 … +85 °C | -60 … +105 °C | |

| Process temperature | -40°C … +180°C/200°C * | -60°C … +180°C/200°C * | |

| Process pressure | -0.8 ~ +0.8MPa * |

-1.0 ~ +5.0MPa * (*) Note that the detailed pressure range is described in the specific antenna type. |

|

| Process connection | Flanges >= DN50 or Thread G2-¼ or NPT | ||

| Signal output | 4-20 mA/HART7 2-wire, 4-20 mA/HART7 4-wire, Profibus PA / DP, Ethernet-APL, Modbus protocol 4-wire | ||

| Variables influencing meas. accuracy |

Specifications for the digital measured value Temperature drift - Digital output: ±1mm/10K relating to the max. measuring range or max. 15 mm Additional deviation through electromagnetic interference acc. to EN-61326: < ±10 mm Specifications apply also to the current output Temperature drift - Current output: ±0.02%/10K relating to the 16.7 mA span or max. ±0.2% Deviation in the current output due to digital/analogue conversion Non-Ex and Ex-ia version: < ±1μA; Ex-d-ia version: < ±1μA Additional deviation through electromagnetic interference acc. to EN-61326: < ±150μA |

||

| Indication/Adjustment(LOI) |

1. 160x80 LCD FSTN RGB backlight monitor adapter with keyboard module, operation Temp. -20°C … 70°C. or 128x64 OLED monitor adapter with keyboard module, operation Temp. -55°C … 80°C.(option) or 230x240 LCD TFT colors monitor adapter with keyboard module, operation Temp. -20°C … 70°C. (option only for 4-wrie system) 2. (APP) Radar MobileManager via BT wireless connection 3. (PC software) Radar PCManager /or Via a PC with PACTware/DTM (an interface converter AiW-305 USB CONNECT is required) |

||

| Power supply | 16V ~ 40 VDC / Load resistor ≈ 600Ω | ||

| Wireless communication | Bluetooth 5.0 (Bluetooth 4.0 LE compatible), communication range 40m, in rainy day 20m | ||

| Approvals |

CLEx/CNEx: Ex ia IIC T6 Ga IP67; Ex d IIC T6 Gb IP67 // SIL2 (No.6G230714.CSETW60) |

||

| Housing | Single chamber / Double chamber, Aluminum / Stainless steel / Plastic PBT, IP66 / IP67 / IP68 | ||

| Applications | Liquids, solids, powder, and stirring and corrosive environment applications | ||

| Document Download |

SE RVICE CONTACT: 86-13799977915, 86-18965063391(TECHNICAL SUPPORT), 86-18106067295(AFTER SALE SERVICE)

ALTHOUGH WE HAVE RECONCILED THE CONTENTS OF THE MANUAL WITH DESCRIPTION OF INSTRUMENT, THERE MAY STILL BE CHANGES WE CANNOT ENSURE THAT IT IS FULLY CONSISTENT. THE CONTENT WILL BE CHECKED AND CORRECTED IN AN

ORDERLY, AND THE ERRATA WILL BE IN SUBSEQUENT RELEASES. WE WELCOME USERS TO MAKE VARIOUS SUGGESTIONS FOR IMPROVEMENT. [TECHNICAL DATA SUBJECT TO CHANGE]

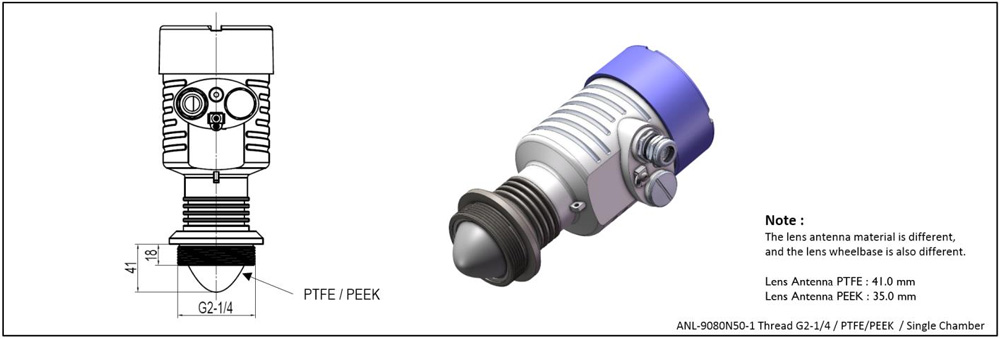

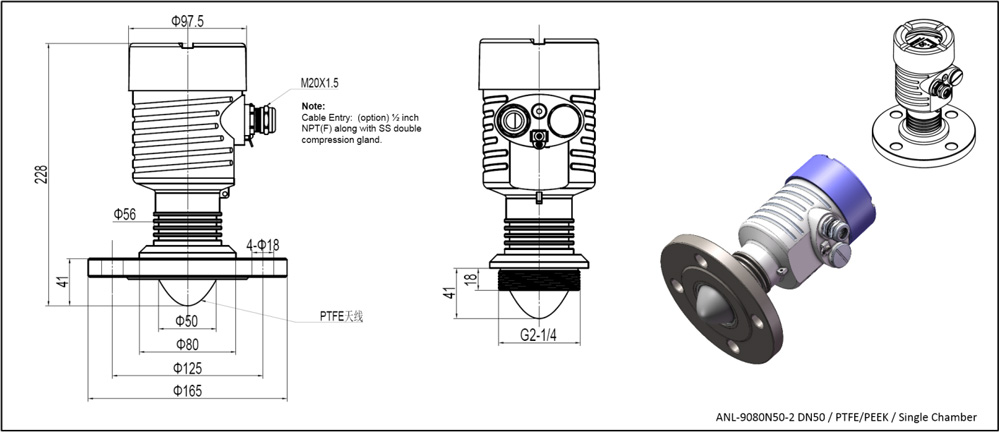

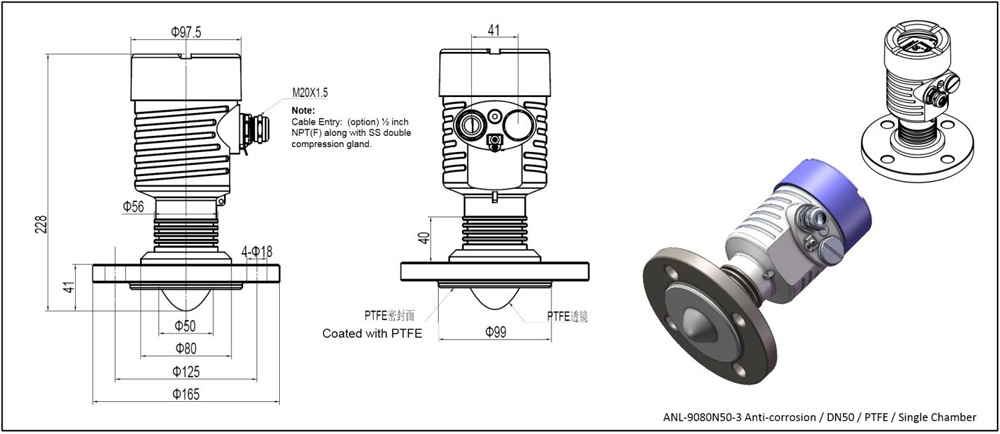

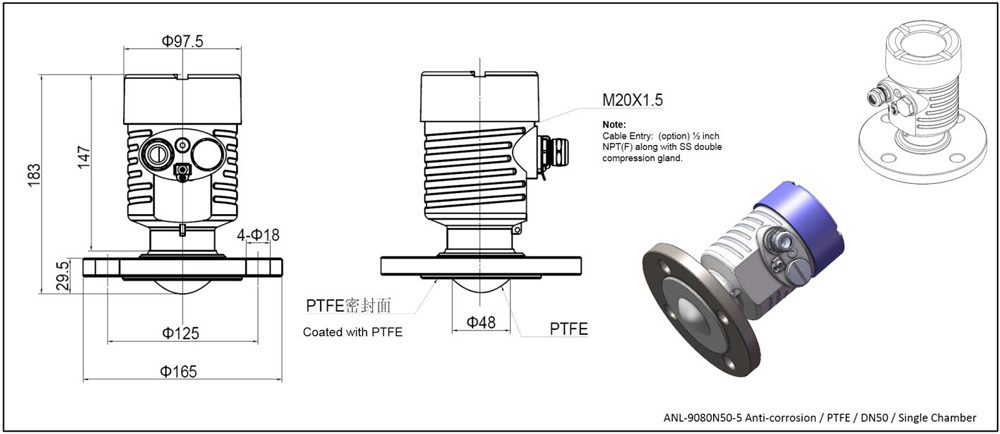

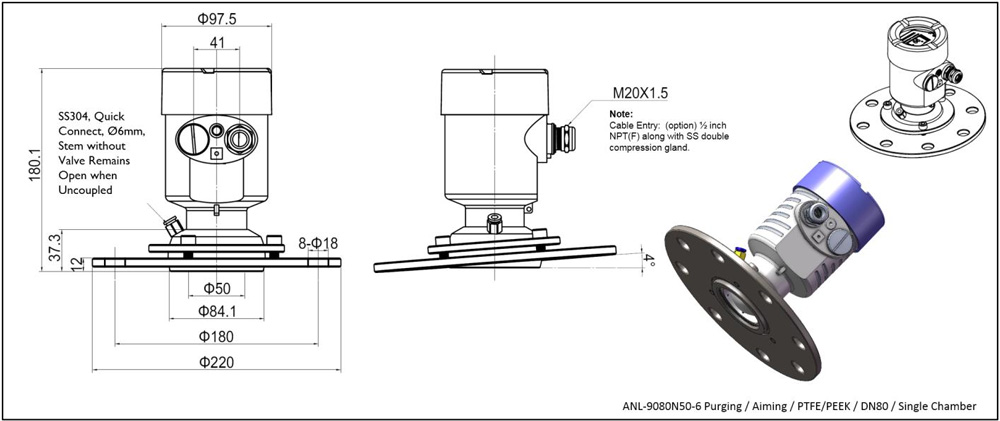

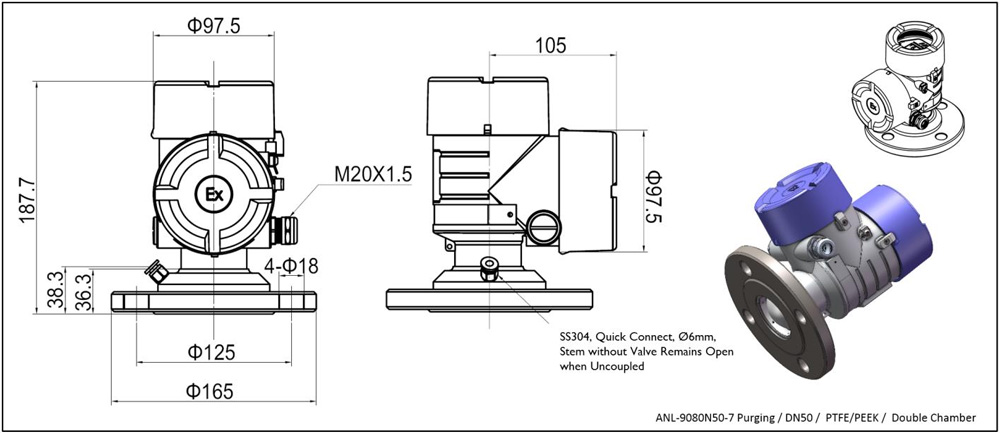

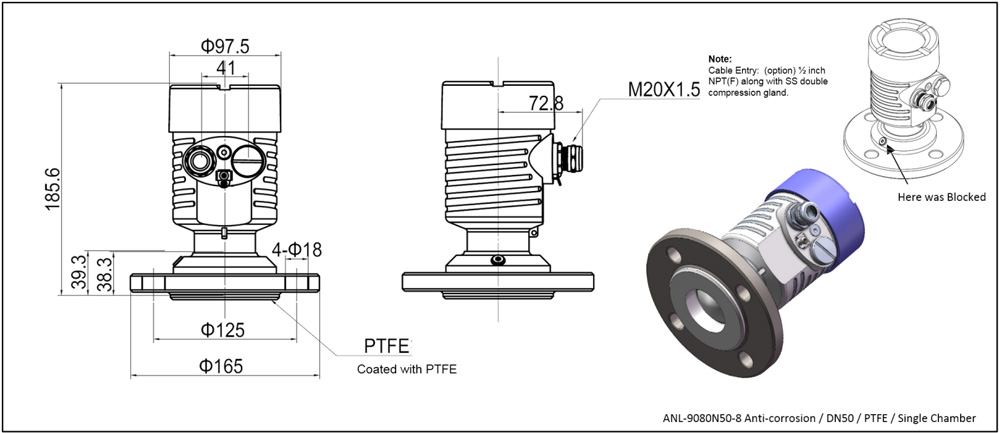

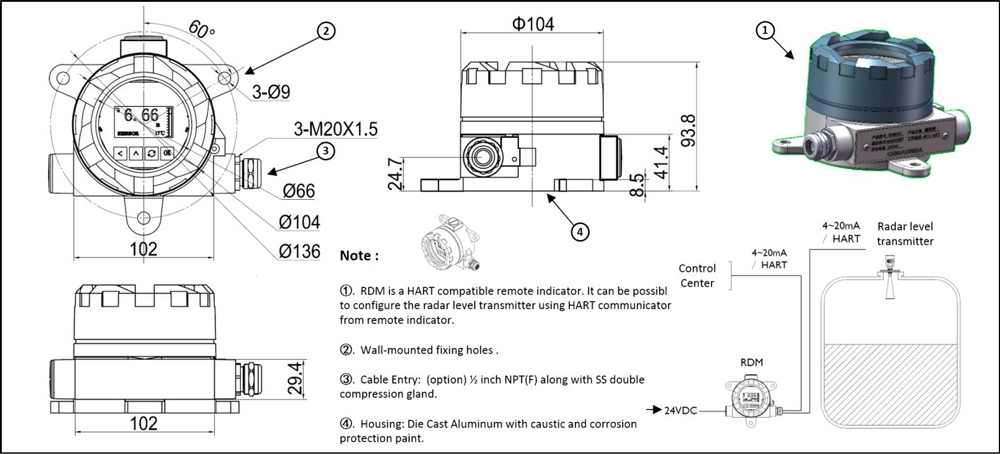

Dimensions

The following dimensional drawings represent only an extract of all possible versions. Detailed dimensional drawings can be downloaded at https://www.chinasimba.com/downloads.html "Drawings".

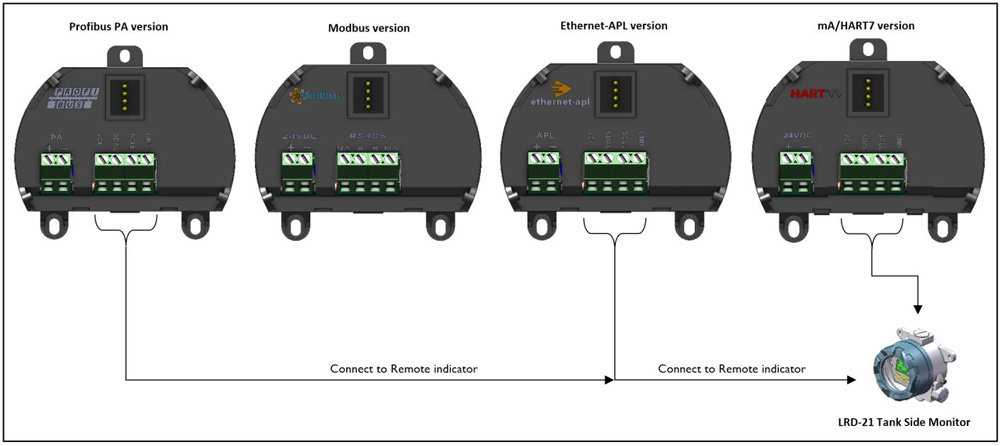

Remote indicator connects for ANL-9080

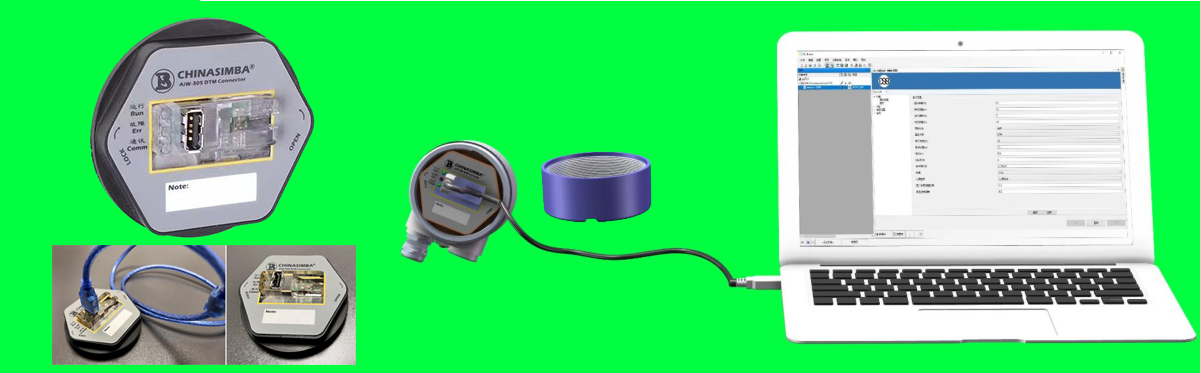

DTM Adapter for ANL-9080

AiW-305 USB Converter Adapter

Remote programmer cum Indicator Adapters

Remote indicator with HART compatible (RDM-25)

Remote indicator via Serial communication (LRD-21)

Remote indicator via Bluetooth communication

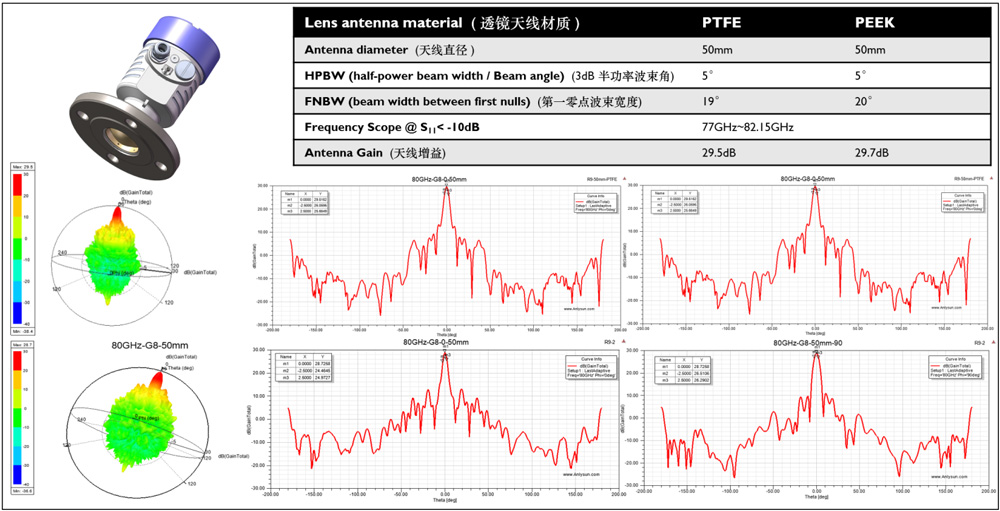

ANL9080 radar level transmitters (with Bluetooth function) can be connected to mobile phone through Bluetooth wireless system. The mobile phone needs to install the RadarMobileManager APP. This is a free registered APP (Android and IOS etc.) software, which can be downloaded and installed directly in major APP Stores, or please contact the relevant product suppliers. The Radar Antenna Specification of the ANL-9080N50

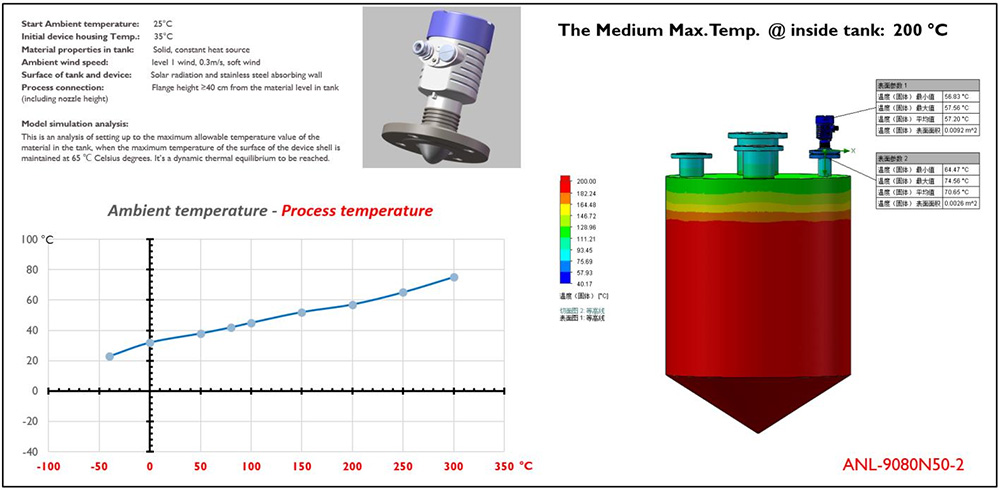

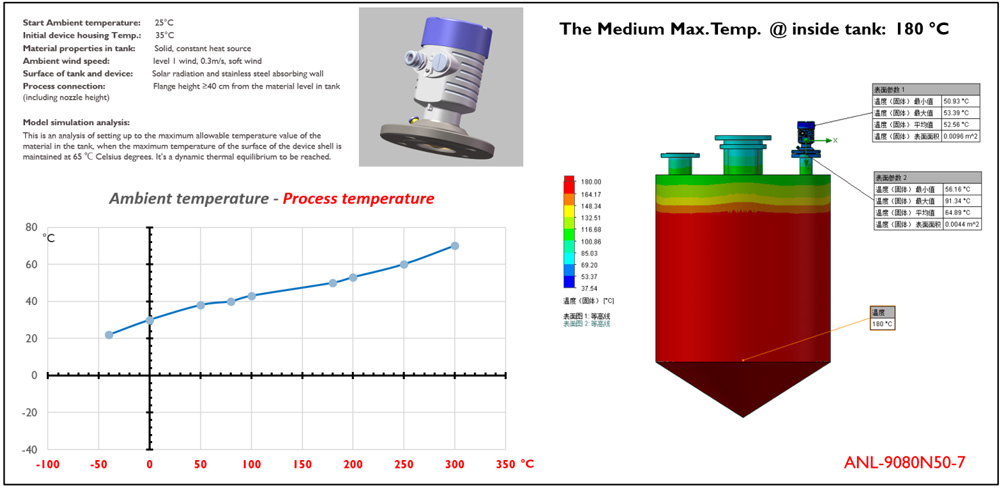

Thermal simulation graph for the ANL-9080N50

Aluminum housing

Stainless steel housing

Plastic housing

Installing Applications

Early Products

ANL9080-DN50 is a frequency modulation radar level transmitter operates at a frequency band around 80GHz with a welded small aperture flange. This transmitter is specifically crafted and designed for small to medium range applications (0.1m to 50m), including level measurements in liquid/powder/paste products. It’s 2-wired powered and has fast responses to level changes. Featuring with its unique Proactive Tracking and Identification Technology that operates at multi-echoes modes which can identify the real echo and reliably return the correct level under harsh conditions; it provides robust measurement for applications like mixing vessels, and process vessels that feed or drains products frequently.

Applications: Petrochemical Industry, Pharmaceutical Industry, Cement Production, Sintering, Food Industry and Bulk Solid

To order or inquire, please contact us

|

Radar Frequency |

76.2 to 80.2GHz dynamic FM sweep bandwidth 4GHz (On demand adjustment on the FM sweep bandwidth is available to comply with ISM requirements) |

| Measuring Range | 10.0m / 50.0m |

| Dead Band | 10mm |

| Measuring Principle | FMCW Radar |

| Resolution | 0.1mm (10m Measuring Range) / 0.5mm (50m Measuring Range) |

| Accuracy | ±2mm (10m Measuring Range) / ±3mm (50m Measuring Range) |

| Antenna Material | PEEK material, Lensed antenna |

| Antenna Beam | 5°/ Antenna Gain 28.7dB |

| Signal Output | 4-20mA, HART5 (Standard configuration) /or HART7 |

| Power Supply | 16V~36VDC / Two-wired |

| Process Conecction | DN50 Flange, with air purge |

| Process Temperature | ‐40 ~ 120℃, or ‐40 ~230℃ (Extra cooling fins are required) |

| Ambient Temperature | ‐40 ~ 85℃,≤95%RH |

| Process Pressure | ‐1 ~ 4MPa or ‐4~12MPa (Extra reinforce flange members are required) |

| Local Configuarable | PC desktop software (Radar PCManger) / 4 on panel push button / Smartphone app and Wechat Mini-program (RadarMobileManger) / Vessel Side Meter |

| WIFI Connection | Bluetooth / LoRa / IOT |

| Comm. Protocol | HART / MODBUS / PROFIBUS (optional) |

| Fail Safe | 22mA or 4mA/20.5mA (configurable) |

| Display | 160x80 dot matrix black and white monochrome display / with backlight(optional 128x64 dotmatrix LCD / with backlight) |

| Enclosure Material | Alluminium alloy made single chamber or dual chamber( 220VAC available for dual chamber only) |

| Cable Connector | M20x1.5 (⌀ 5...9mm) |

| IP Rating | IP67 (electronic compartment filled with silica gel) |

| Approval | CNEX: Ex ia IIC T6 Ga |

| Package Size | L x W x H 435mm x 275mm x 275mm |

| Application | Liquid, Solid (Recommended for small range), Powder (Recommended for small range), Paste |